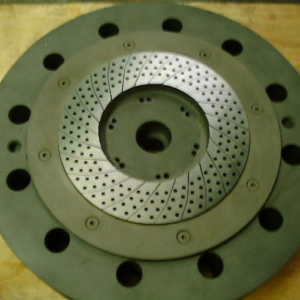

Extrusion Dies

Great Lakes Industrial Knife specializes in the design, manufacture, and repair of high-quality extrusion dies. Our advanced technology and skilled craftsmanship ensure that every die we produce meets the highest standards of precision and durability. Whether you need custom-designed dies for unique applications or reliable repair services to extend the life of your existing dies, we have the expertise and commitment to deliver excellence.

Precision manufactured and machined to OEM specifications or custom design.

- CPM 10V, CPM 15V, stainless steel S90V, are just a few of the powdered metals used.

- Stellite® hard facing and weld repair.

- Proudly made in the USA by skilled machinists

Applications

Plastic Extrusion

Producing pipes, profiles, films, and sheets with precise dimensions and high-quality finishes.

Rubber Extrusion

Creating durable, uniform rubber products for automotive, industrial, and consumer applications.

Metal Extrusion

Fabricating complex shapes and profiles for the construction, aerospace, and manufacturing industries.

Contact Our Team

Leverage our decades of experience to solve your strand pelletizer feed roll challenges.

Custom Die Manufacturing

Tailored Designs

Our team works closely with you to understand your specific requirements, creating custom extrusion dies that meet your exact specifications.

Advanced Materials

Utilizing top-grade materials, our dies are built to withstand the rigors of high-pressure extrusion processes, ensuring long-term performance and reliability.

Precision Engineering

State-of-the-art CAD/CAM technology and CNC machining guarantee that each die is manufactured to precise tolerances, ensuring optimal performance and consistency.

Made in the USA

Great Lakes Industrial Knife manufactures and repairs extrusion dies right here in the USA for the plastic compounding industry.

Comprehensive Repair Services

Expert Diagnostics

Our skilled technicians conduct thorough inspections to identify and address wear, damage, and other issues affecting die performance.

Precision Refurbishment

Using advanced repair techniques, we restore your dies to their original specifications, extending their lifespan and maintaining their performance.

Quick Turnaround

We understand the importance of minimizing downtime, which is why we offer expedited repair services to get your operations back up and running swiftly.

Why Choose Great Lakes Industrial Knife?

Industry Expertise

With decades of experience in rotor manufacturing, we understand the challenges of pelletizing and offer solutions that meet the highest standards of performance and reliability.

Customer-Centric Approach

We work closely with our customers to understand their unique needs and provide tailored solutions that enhance their operational efficiency and productivity.

Made in the USA

Our skilled machinists and engineers can produce or repair all types of bolt-on, wedge lock, solid head helical pelletizer rotors and bed knives right here in the USA, which reduces lead times and transportation costs.

Benefits

Enhanced Production Efficiency

- Consistent Quality: Our precision-engineered dies ensure uniform product quality, reducing waste and improving production efficiency.

- Increased Throughput: With optimized design and superior materials, our dies enable higher extrusion speeds, maximizing your production capacity.

Cost Savings

- Durable Construction: High-quality materials and meticulous craftsmanship result in dies that last longer, reducing the frequency of replacements and associated costs.

- Reduced Downtime: Fast, reliable repair services help you minimize downtime and maintain continuous production, enhancing overall profitability.

Technical Expertise

- Innovative Solutions: Our engineering team leverages the latest industry advancements to provide innovative solutions that address complex extrusion challenges.

- Comprehensive Support: From initial consultation through ongoing maintenance, we offer comprehensive support to ensure your extrusion operations run smoothly.