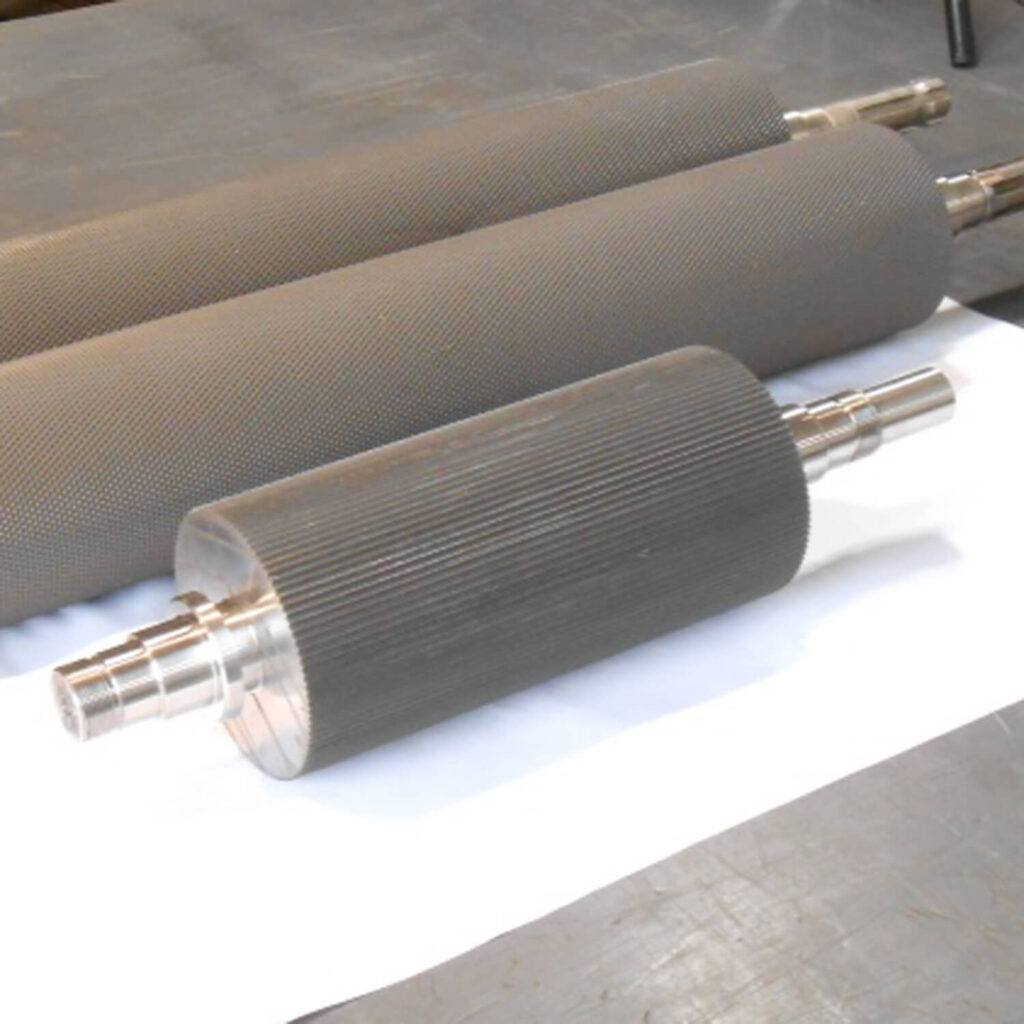

Feed Rolls & Pull Rolls & Pelletizer Roller Repair

Great Lakes Industrial Knife specializes in manufacturing top-quality feed rolls and pull rolls designed to enhance your pelletizing and plastic production processes. When it comes to the efficiency of your pelletizing operation, the condition of your feed rolls and pull rolls can have a huge impact on product quality, process stability, and optimization of production costs.

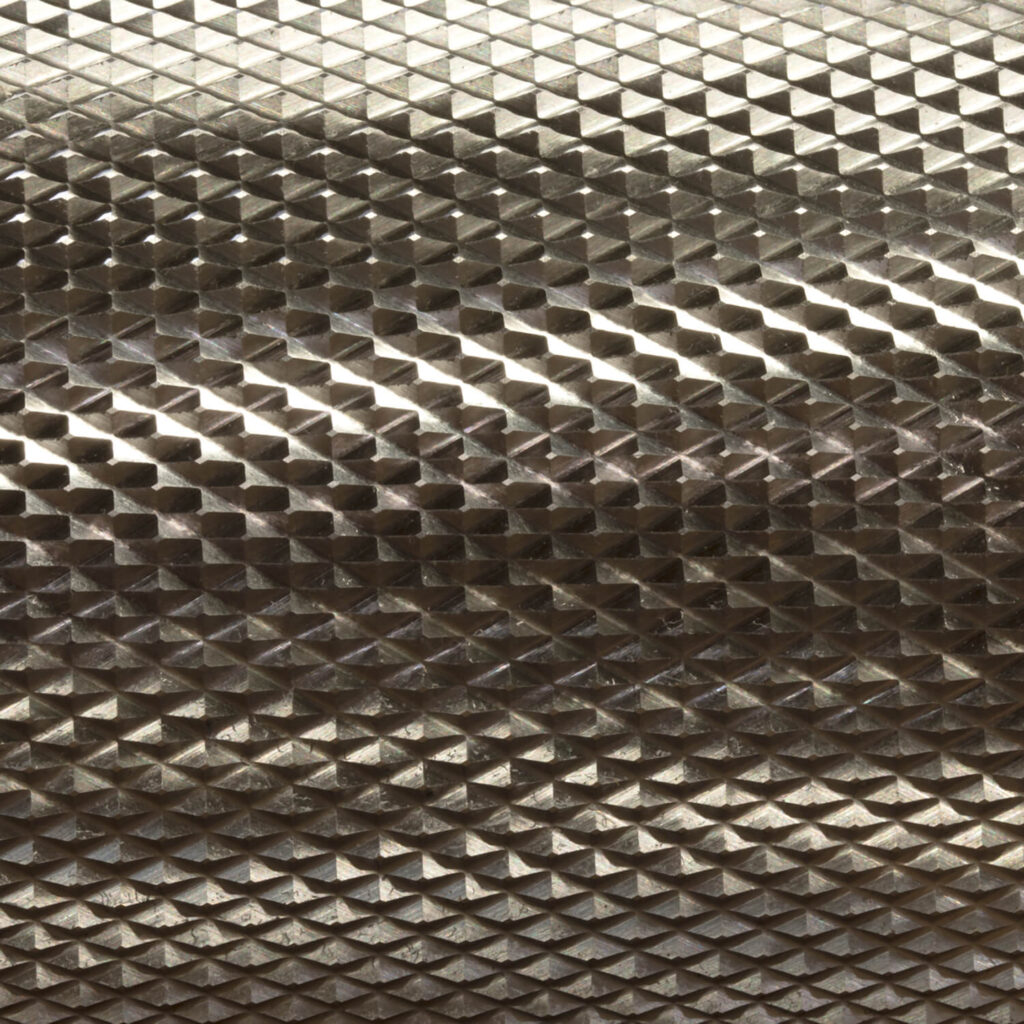

Why run the risk of variable pellet sizes, increased waste, and more wear and tear on your operation? New or repaired feed rolls with the proper “grip” can improve optimization and reduce costs.

- Consistent Performance: Our precision-engineered feed and pull rolls ensure smooth, uninterrupted operation, reducing waste and increasing throughput.

- Reduced Downtime: High durability and low maintenance requirements help minimize downtime, keeping your production lines running efficiently.

- Uniform Output: Achieve consistent, high-quality pellets and plastic products with our reliable rolls, which maintain precise feeding and pulling actions.

- Improved Material Handling: Smooth and steady material movement ensures the highest quality in your final products, meeting stringent industry standards.

- Made in the USA: Great Lakes Industrial Knife manufactures and repairs feed rolls and pull rolls for virtually all strand pelletizer makes and models right here in the USA.

- Longevity: Feed rolls from Great Lakes Industrial Knife are designed for maximum service life, reducing the frequency and cost of replacements.

- Maintenance Efficiency: Easy-to-maintain designs minimize labor and downtime associated with roll changes and repairs, contributing to lower operational costs.

Why Choose Great Lakes Industrial Knife?

Expertise and Innovation

With years of experience and a commitment to innovation, we provide cutting-edge solutions that meet the most demanding production challenges.

Customer-Centric Approach

We focus on understanding and addressing your specific needs, offering personalized service and support to ensure your complete satisfaction.

Contact Our Team

Leverage our decades of experience to solve your strand pelletizer feed roll challenges.

Key Features

Feed Rolls

Superior Material Construction

- High-Grade Materials: Constructed from premium-quality rubber, polyurethane, and other wear-resistant materials, our feed rolls ensure long-lasting performance.

- Precision Engineering: Manufactured to exacting standards, our feed rolls deliver consistent feeding, reducing downtime and maintaining high productivity. Our skilled engineers and machinists can make or repair virtually every feed roll configuration.

Optimized Performance

- Smooth Operation: Designed to provide a steady and reliable feed, our rolls minimize material slippage and ensure uniform pelletizing, enhancing the overall quality of your output.

- Durability: Our feed rolls are built to withstand the rigors of continuous operation, maintaining their integrity and performance over extended periods.

Stellite® is a registered trademark of Deloro Stellite Company Inc.

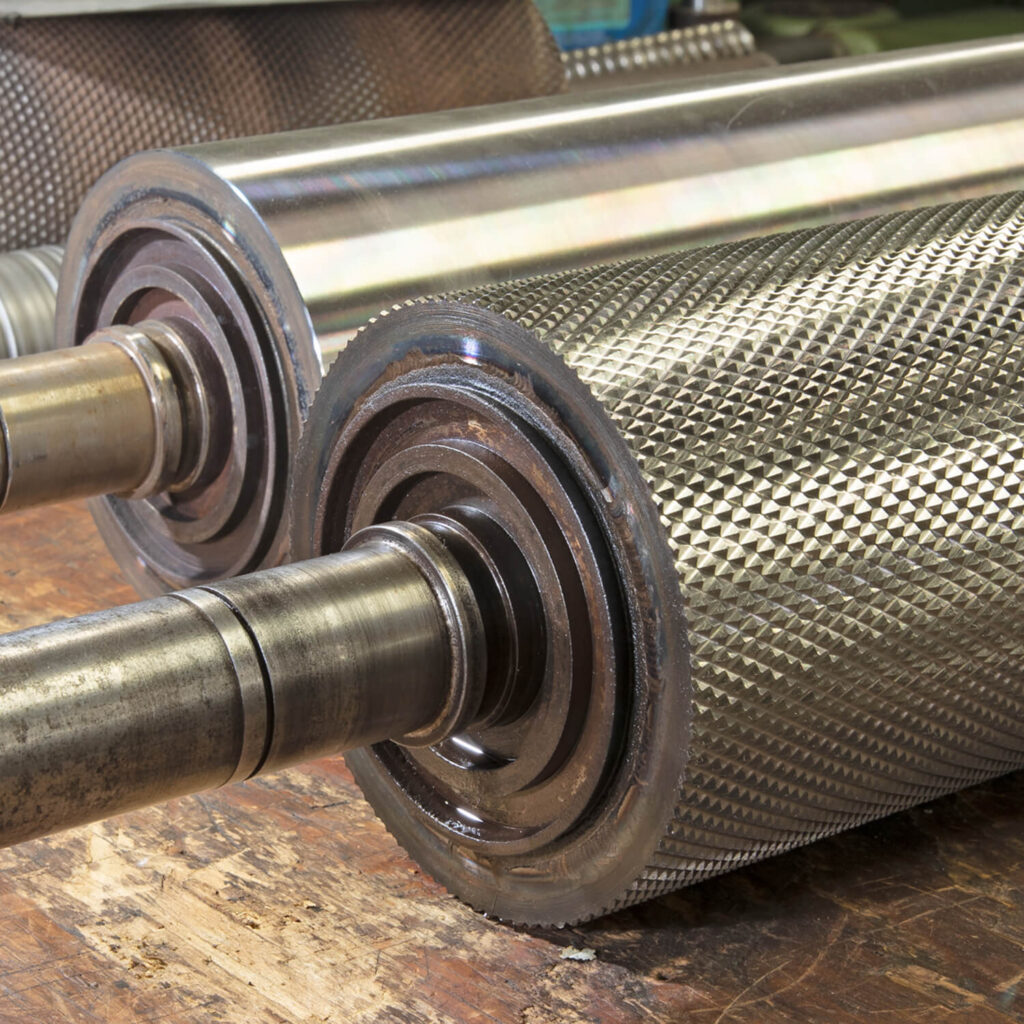

Pull Rolls

Robust and Reliable

- Heavy-Duty Construction: Our pull rolls are crafted from durable materials, such as hardened steel and high-performance elastomers, to handle high-stress environments.

- Precision Tolerances: Engineered for precision, our pull rolls maintain consistent tension and alignment, crucial for producing high-quality plastic products.

Versatile Applications

- Wide Compatibility: Our pull rolls are designed to fit a variety of plastic production and pelletizing equipment, offering flexibility and ease of integration.

- Custom Solutions: We provide tailored roll designs to meet specific operational needs, ensuring optimal performance in any application.