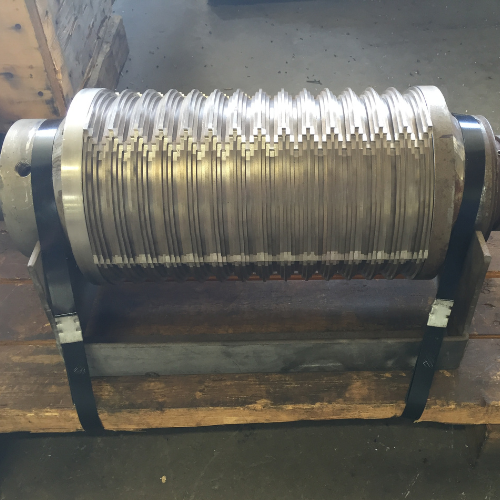

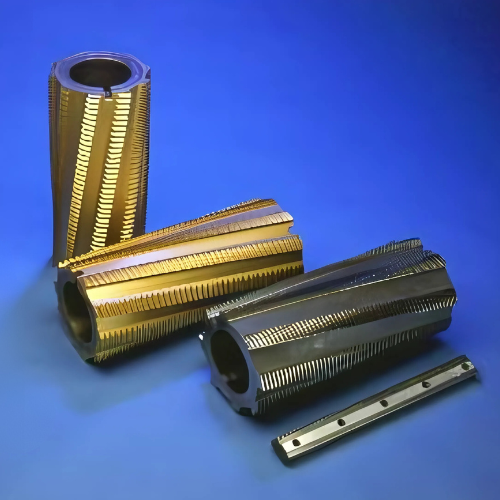

Dicer & Dicer Bed Knives

Great Lakes Industrial Knife manufactures top-of-the-line pelletizing dicers and dicer bed knives designed to enhance your pelletizing process. Our products are engineered to deliver superior cutting performance, durability, and efficiency, ensuring that your operations run smoothly and produce high-quality pellets. Whether you need new equipment or replacement knives, our solutions meet the highest industry standards.

Great Lakes Industrial Knife offers a complete line of dicers and dicer bed knives for all machine makes and models including,

-

Bolton® Dicers

-

Cumberland® Stair Step Dicers

-

Henion® Dicers

-

Sagitta® Dicers

-

Stacked® Disc Dicers

-

And More!

- Precision-manufactured matched sets.

- CNC sharpening to OEM specs, 0.0005″ concentricity.

- Complete MIG weld tooth repairs

- Exact tooth profile – mirror finishes.

- Tungsten carbide surface coatings

- Bed knives and platten bars.

- Proven extreme-condition materials for maximum wearability, toughness, and productivity.

- High wear alloy tool steels

- High speed tool steel

- Powdered metals, CPM 10v®, CPM M4®

- ICE™ Inlaid Carbide Extreme

Stellite® is a Registered Trademark of Deloro Stellite Company Inc., Ferro-TiC® is a registered trademark of Pacific Sintered Metals, CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Contact Our Team

Leverage our decades of experience to solve your various machine knife challenges.

Pelletizing Dicer Bed Knives

Precision Manufacturing

- Exacting Tolerances: Our dicer bed knives are manufactured to precise tolerances, ensuring a perfect fit and optimal cutting performance every time.

- Durable Construction: Crafted from wear-resistant materials, our knives maintain sharpness and effectiveness even under heavy use, extending their operational lifespan.

Versatile and Customizable

- Wide Compatibility: Our bed knives are compatible with a variety of pelletizing dicers, making them a versatile choice for different production setups.

- Custom Solutions: We offer custom knife designs tailored to your specific needs, ensuring that you get the perfect solution for your pelletizing process.

Key Features

Superior Cutting Precision

- Advanced Design: Our dicers feature innovative designs that ensure consistent, precise cuts, producing uniformly sized pellets.

- High-Quality Materials: Made from premium-grade steel and alloys, our dicers are built to withstand the rigors of high-volume pelletizing, offering exceptional durability and longevity.

Efficiency and Reliability

- Optimized Performance: Engineered for maximum efficiency, our dicers minimize energy consumption while maximizing throughput, enhancing your production capacity.

- Reduced Maintenance: Designed for easy maintenance and long service life, our dicers help you minimize downtime and reduce operational costs.

- Made in the USA: Our skilled engineers and machinists manufacture or repair virtually any type of dicer right here in the USA.

Benefits

Enhanced Product Quality

- Consistent Pellet Size: Our precision-engineered dicers and knives produce uniform pellets, improving the quality and consistency of your final product.

- Smooth Cutting Action: Advanced design and materials reduce stress and wear, resulting in cleaner cuts and better overall pellet quality.

Operational Efficiency

- Increased Throughput: Efficient cutting mechanisms and high durability enable higher production speeds, boosting your output and productivity.

- Lower Costs: Reduced maintenance requirements and extended product lifespan translate to lower operational and replacement costs over time.

Expert Support

- Technical Assistance: Our team of experts is available to provide guidance and support, from selecting the right products to optimizing your pelletizing process.

- Ongoing Service: We offer comprehensive maintenance and repair services to keep your equipment in top condition, ensuring continuous, reliable operation.

Why Choose Great Lakes Industrial Knife?

Innovation and Quality

With a commitment to innovation and quality, we deliver cutting-edge solutions that meet the highest standards of performance and reliability.

Customer-Centric Approach

We prioritize your needs, offering personalized solutions and exceptional customer service to ensure your complete satisfaction.