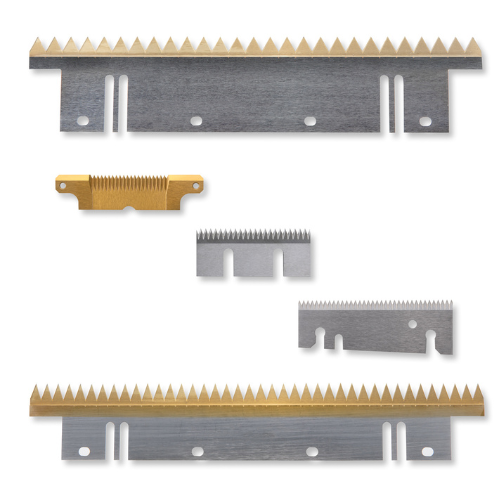

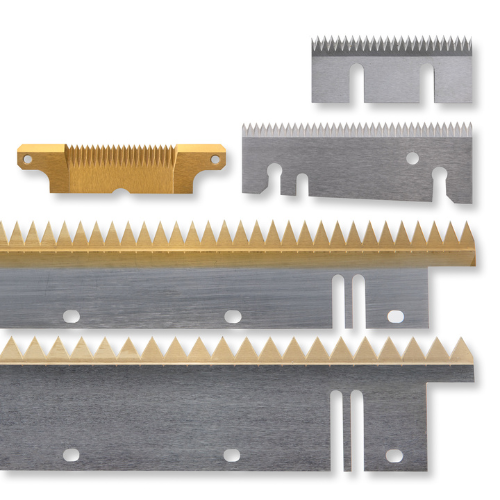

Perforating Blades

Great Lakes Industrial Knife specializes in manufacturing high-performance perforator knives and blades designed for precise and efficient operations across a variety of industries. Our commitment to innovation and quality ensures that you get the best tools to optimize your production processes.

High-Quality Perforator Knives

Exceptional Blade Sharpness

Our Perforator knives deliver clean, consistent perforations, reducing waste and improving efficiency.

Robust Durability

Crafted from premium-grade materials, our knives are built to withstand intense industrial use.

Versatile Designs

Suitable for a wide range of materials including paper, film, foil, and non-wovens.

Custom Perforation Solutions

Tailored to Your Needs

We design and manufacture custom knives to meet your specific perforation requirements.

Rapid Production

Enjoy quick turnaround times without compromising on precision or quality.

Expert Collaboration

Work with our skilled engineers to develop solutions that enhance your operational efficiency.

Contact Our Team

Leverage our decades of experience to solve your various machine knife challenges.

- Alloy tool steels

- D-2 High carbon/High chrome tool steel

- High speed steels

- High performance stainless steels

- Powdered metals, CPM 10V®, CPM M4®

- Zirconia ceramics

- Solid tungsten carbide

- ICE™ Inlaid Carbide Extreme

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

Perforator Knives from Great Lakes Industrial Knife are precision manufactured to extremely close tolerances to produce razor sharp edges.

- Precision ground tooth profiles

- Cut & Tie widths to meet any profile.

- Mini-Perfs

- Dust free edge technology.

- Mirror bevel finishes – razor sharp

- Available from stock

- Computerized inventory control

- Expert regrind service – match ground sets

- Proven extreme condition materials for maximum wearability and production.

Why Choose Great Lakes Industrial Knife?

Advanced Manufacturing Technology

Our cutting-edge production facilities utilize the latest technology to ensure each knife is made to the highest standards. Precision machining and advanced heat treatments ensure optimal performance and longevity.

Rigorous Quality Control

We implement stringent quality control measures at every stage of production. From raw material selection to final inspection, each knife meets our exact standards for excellence.

Superior Customer Support

Our dedicated support team is with you every step of the way, from selecting the right knife to providing after-sales service. We’re committed to helping you achieve the best results in your perforation processes.

Industries We Serve

Achieve perfect perforations for coupons, tickets, and tear-off sections.

Enhance product functionality with precise perforations in packaging materials.

Reliable performance for perforating non-woven fabrics and other materials.

Efficient perforation for packaging solutions in the food industry.