Shear Blades & Rotary Shears

Great Lakes Industrial Knife specializes in manufacturing top-of-the-line shear blades and rotary shears designed to meet the rigorous demands of the metalworking industry. Our products are engineered for precision, durability, and exceptional performance, ensuring you get the best results for your cutting operations.

Great Lakes Industrial Knife Manufactures Shear Blades for all OEM Makes and Models including but not limited to:

- Accur-Shear®

- Adira®

- Amada®

- American Hercules®

- Atlantic®

- Betenbender®

- Chicago®

- Cincinnati®

- Cleveland Crane®

- Darley®

- Di-Arco®

- Dreis & Krump®

- Delta Brands®

- Edwards/Pearson®

- Famco®

- Gary®

- Guifil®

- Herr-Voss®

- HTC®

- Hydrapower®

- Lodge & Shipley®

- Loopco®

- LVD®

- Morgan®

- Murate Weidmann®

- National®

- Niagra®

- Pacific®

- Paxson®

- Pexto®

- Promecam®

- Pullmax®

- Rhodes®

- Roper-Whitney®

- Safan®

- Scottish®

- Steelweld®

- Summit®

- Tennsmith®

- Wean®

- Welty Way®

- Wysong & Miles®

- Yoder®

Contact Our Team

Leverage our decades of experience to solve your various machine knife challenges.

Shear Blades

Our shear blades are crafted to deliver clean, precise cuts every time. Whether you’re cutting steel, aluminum, or other metals, our blades offer unparalleled reliability and efficiency.

Key Features:

- Premium Materials: Made from high-quality alloys to ensure longevity and resistance to wear.

- Precision Ground: Engineered to exact specifications for smooth, accurate cuts.

- Custom Sizes: Available in standard and custom dimensions to fit a variety of shearing machines.

- Advanced Heat Treatment: Enhances blade hardness and durability for prolonged use.

- Consistent Performance: Maintains sharpness and cutting quality even in high-volume applications.

Rotary Shears

Our rotary shears are designed to deliver seamless cutting performance, providing smooth and precise cuts for various metalworking applications. With a focus on durability and precision, our rotary shears help you achieve superior results.

Key Features:

- High-Quality Construction: Built from robust materials to withstand rigorous use.

- Sharp Cutting Edges: Maintained through precise manufacturing processes for optimal cutting performance.

- Versatile Design: Suitable for cutting a wide range of metals including stainless steel, copper, and aluminum.

- Customizable Options: Tailored to fit your specific machine and cutting requirements.

- Reduced Downtime: Engineered for longevity, minimizing the need for frequent replacements.

- High shock tool steels

- D-2 High carbon/High chrome tool steel

- ICE™ Inlaid Carbide Extreme

Our Shear Blades and Rotary Shears are precision manufactured to extremely close tolerances.

- Computerized inventory control

- Stock delivery on standard knives.

- Short lead times on non-stock blades

- Expert in house sharpening service – match ground sets.

- Mig weld nick and chip repairs

- Demagnetizing

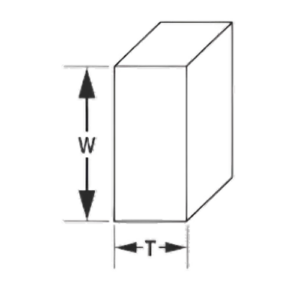

Shear Blades Grinding Limits

| Original Size | Minimum Width (W) | Minimum Thickness (T) |

| 3.000 x 1.000 | 2-5/8″ | 3/4″ |

| 4.000 x 1.000 | 3-5/8″ | 3/4″ |

| 5.000 x 1.125 | 4-5/8″ | 7/8″ |

| 5.500 x 1.50 | 5-1/8″ | 1-1/4″ |

| 6.500 x 1.750 | 6-1/8″ | 1-1/2″ |

Shear Blades Specifications