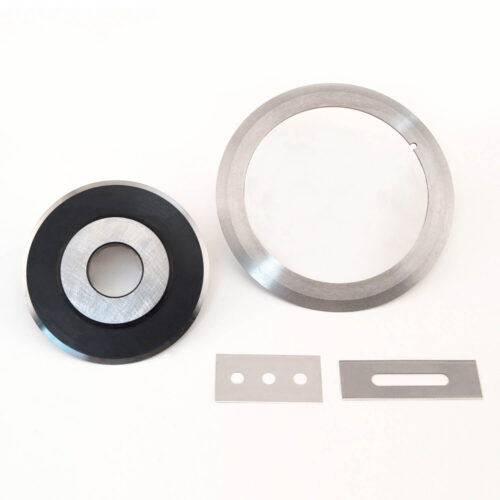

Slitter Knives

Great Lakes Industrial Knife specializes in manufacturing high-performance industrial slitter knives. Our expertly engineered slitter knives are designed to meet the rigorous demands of various industrial cutting applications, ensuring precision, durability, and efficiency.

- Paper and Cardboard

- Plastic Films

- Foil and Metal

- Textiles and Nonwovens

- Rubber and Plastics

- Packaging Materials

- Alloy tool steels

- D-2 High carbon/High chrome tool steel

- High speed steels

- High performance stainless steels

- Powdered metals, CPM 10V®, CPM M4®

- Zirconia ceramics

- Solid tungsten carbide

- ICE™ Inlaid Carbide Extreme

CPM 10V®, CPM M4® are registered trademarks of Crucible Materials Corp.

All Slitter Knives manufactured by Great Lakes Industrial Knife are precision engineered to extremely close tolerances to produce razor sharp edges. Call us today at (888) 665-1200, email us at sales@glknife.com, or use the form at the bottom of this page to leverage our decades of experience to solve your Slitter Knife challenges.

- Proudly manufactured and sharpened in the USA by skilled machinists.

- Leverage our rapid response manufacturing to get your parts in a matter of weeks – not months!

- Dust free edge technology.

- Super finished bevels

- Mirror bevel finishes – razor sharp

- Available from stock

- Computerized inventory control

- Expert regrind/sharpening service – match ground sets

- Proven extreme condition materials for maximum wearability, and production.

Key Features

- Premium Materials: Crafted from high-grade steel and other top-quality materials, our slitter knives offer exceptional sharpness, strength, and longevity, even under the most challenging conditions.

- Precision Engineering: Each slitter knife is meticulously engineered for optimal sharpness and alignment, providing clean, accurate cuts that improve product quality and reduce waste.

- Custom Solutions: We provide a variety of sizes, edge profiles, and coatings tailored to your specific needs. Our custom slitter knives are designed to fit seamlessly into your machinery and processes, enhancing performance and efficiency.

- Consistency and Reliability: Advanced manufacturing processes ensure uniformity and consistency across all our slitter knives, guaranteeing reliable performance and repeatable results in your cutting operations.

Contact Our Team

Leverage our decades of experience to solve your various machine knife challenges.

Why Choose Great Lakes Industrial Knife?

Unmatched Precision

Our slitter knives deliver the highest level of precision, ensuring smooth, clean cuts that enhance the quality of your finished products and minimize material waste.

Durability and Longevity

Manufactured from the finest materials and subjected to rigorous quality control, our slitter knives offer superior wear resistance and durability, reducing the need for frequent replacements and maintenance.

Enhanced Efficiency

The sharpness and consistency of our slitter knives boost your operational efficiency, leading to increased productivity and lower operational costs.

Tailored Solutions

We understand that every application is unique. Our team works closely with you to develop custom slitter knives that meet your specific requirements, providing solutions that perfectly align with your production goals.

Exceptional Customer Support

From initial consultation to after-sales service, our dedicated team of experts is here to support you every step of the way, ensuring you get the most out of our products.

Knife-Edges

Regardless of the material being slit, score-cut knives should have rounded edges. Experience may show that other combinations of included angles and edge radii may give more satisfactory results on some materials. These illustrations, however, should be used as a guide. The cross-sections show the mean radius of each class of edge magnified approximately 60 times.

“A” Edge .002 to .004 Radius

“B” Edge .006 to .008 Radius

“C” Edge .010 to .012 Radius

A – 30° Included Angle

Cellophane Board, Pressure Sensitive Tape, Cork, Linoleum, Acetate

B – 30° Included Angle

Paper Back Foil, Waxed Paper, Rubber, Plastic, Surgical Adhesive, Pulp

C – 45° Included Angle

Waxed Paper, Impregnated Paper

B – 60° Included Angle

Gauze, Textiles, Non-Woven

B – 45° Included Angle

Tissue, Newsprint, Crepe Paper, Kraft Paper, Mica Tape, Masking Tape

C – 60° Included Angle

Sandpaper, Abrasive Fabrics

Shear Cut

These two illustrations show the cutting-edge angles that have been successfully used on converter and mill-type winders. Our specialists will recommend the best cutting edges for some materials.

30 °

Used on smaller diameter shear-cut knives such as those used on converter type winders.

45 °

Used on larger diameter shear-cut knives such as those used on mill type winders.